Total Productive Maintenance,TPM

u What is TPM?

TPM focuses on getting the entire workforce involved in maintaining equipment and emphasizes proactive and preventive maintenance that eventually lead to fewer breakdowns, a safer workplace and better overall performance.

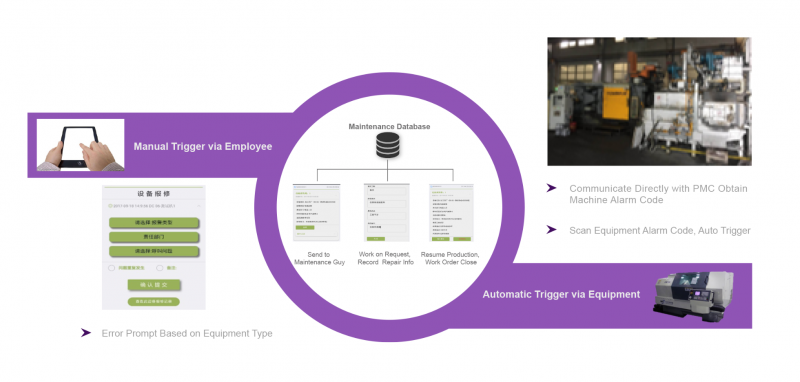

Equipment Ledger, Inspection, Maintenance, Repair and Other Digital Management

Emergency Repair, Planned Maintenance, Equipment Inventory, Spare Parts Management

Common Error Management, Automatic Reporting System

Error and Predictive Alarm System, Section Auto Debugging and Repair

OEE Automatic Generation

u Why TPM?

u The essence of TPM - 3 management ideas

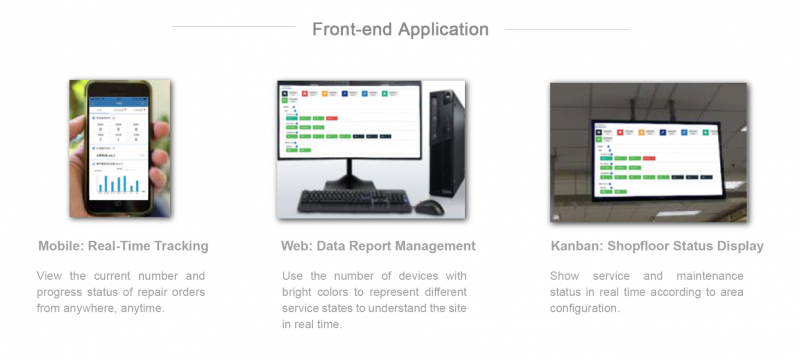

u Application